EPOXY GROUTS

-

…for Machinery Mounting and Anchoring

Standard and X-tra Fluid Grout

Compressive Strength 16,800 psi

Tensile Strength 4,260 psi

Flexural Strength 6,800 psi

Micorox Deep Pour Grout

Compressive Strength: 13,820 psi

Tensile Strength: 1,950 psi

Flexural Strength: 3,750 psi

♦QUICK ACHIEVEMENT OF STRENGTH Develop 9000 psi compressive strength in only six hours and machine is operable. Mill-wright costs and downtime are minimized.

♦SMOOTHER MACHINE OPERATION Micorox Grouts high flow rate and penetration offers minimal shrinkage, complete fill under machine bases. . . fills cracks and voids to rebuild and strengthen foundations and absorb impact and vibrations.

♦QUICK REGROUTING Micorox grouting techniques eliminate removal and resetting of your machine in many cases. Just raise and relevel – then regrout. Reduce downtime from weeks to as little as one day.

♦EASIER SETTING OF ANCHORBOLTS Eliminate expensive equipment for punching wide holes in concrete. Just drill a hole the size of bolt-head and grout.

♦HIGH CHEMICAL RESISTANCE Once set up, Micorox Epoxy Grouts are unaffected by water, humidity, oil, grease and most chemicals.

♦CONVENIENT ALL IN ONE PACKAGE All components are packed in the mixing container. Materials are pre-proportioned for easy mixing and placing. Micorox Epoxy Grouts are just a few of the industrial and commercial polymer systems available from Micor Co., Inc. Other unique products include:

• Specialty flooring systems: industrial and commercial.

• Complete line of industrial polymer tank liners and backing systems.

Read about Micorox Grout many Applications and Advantages.For more information visit each epoxy grout product page listed to the left and download their PDF fact sheets. Contact one of our representatives to assist you in choosing the right product for your specific needs.

-

……… is an exceptionally high strength, fast setting epoxy material designed for grouting, regrouting and anchoring equipment. The product is a two-component, 100% solids epoxy with superior flow rates for easy penetration under machine bases or sole plates.

PROPERTY VALUE

Compressive Strength: 16,800 psi

Tensile Strength: 4,260 psi

Flexural Strength: 6,800 psi

The grout resists vibration and impact and has compressive strengths up to 16,800 psi. This outstanding material may also be used to construct level bases without transits or other leveling equipment, and is ideal for anchoring bolts.

Use Standard Grout when clearance is 1/2 to 1 inch.

-

… is a three component, 100% solids epoxy system used in grouting heavy machinery and other equipment to thicknesses of 12 inches. Deep Pour is far superior to cement grouts. It provides resistance to high impact, vibration, torque loads and other stresses and offers corrosion resistance to water, oil, solvents and a wide variety of other chemicals.

Deep Pour Grout substantially reduces long term grouting costs since it is not subject to the failures associated with cement and iron-filled cement grouts. Deep Pour Grout offers cured strengths of 13,820 psi to 17,000 psi.

PROPERTY VALUE

Compressive Strength: 13,820 psi

Tensile Strength: 1,950 psi

Flexural Strength: 3,750 psi

-

…combines Superior Flow rates, High Physical Strengths and Color Matching capabilities with LOW ODOR to provide a low Viscosity grout for use in healthcare or commercial environments where safety, appearance and performance are important.

PROPERTY VALUE

Compressive Strength: 16,800 psi

Tensile Strength: 4,260 psi

Flexural Strength: 6,800 psi

…for Machinery Mounting and Anchoring

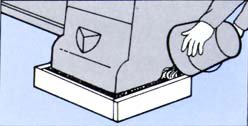

Pouring epoxy grout under machine foot

Micorox epoxy grout is fast setting 100% solids epoxy systems which yield exceptionally high strength and need minimal surface preparation. That means installation is quick and trouble free, virtually eliminating costly machine down time.

Material, equipment and labor costs are greatly reduced too! In most cases machines can be reset without removal-just raise and level the machine and regrout it. Anchoring bolts is a quick and efficient job with Micorox; just drill a hole slightly larger than the bolt and pour in the Micorox grout to anchor as desired. Normally, operation can be resumed within 6 hours.

How to apply Epoxy Grout under Skid Mounted Machines

1 – Level Machine with 1/4″3/4″ Clearance for grout

2 – Dam Perimeter Leaving Adequate Venting for grout

3 – Mix Micorox Grout (2 – 3 minutes)

4 — Pour Under Machine and Let grout harden

Micor Company Epoxy Grouts

Our Micorox grouts are fast setting 100% solid epoxy systems with exceptionally high strength that need minimal surface preparation for anchoring and installing heavy industrial machinery. Industries that use our grout include food plants, pharmaceutical plants, chemical plants, battery plants, institutional facilities and pulp and paper mills.

Equipment that use our epoxy grout are: Compressors, Lathes, Pumps, Engines, Electric Motors, Generators, Presses, Crushers, Paper Machines, X-ray Machines, Grinders, Truck Scales, Punches, Hoist and Jib-Crane Bases.

Installation is quick and trouble free, virtually eliminating costly machine down time.

Material, equipment and labor costs are greatly reduced using our systems of machinery mountings.

In most cases machines can be reset without removal – just raise and level the machine and re-grout it. Anchoring bolts installation is a quick and efficient job with Micorox epoxy grout. Normally, full operation of the machinery can be resumed within 6 hours of mounting machinery or replacing existing mounting bolts.

Micorox Epoxy Grout Advantages

QUICK ACHIEVEMENT OF STRENGTH

Develop compressive strength in only six hours and machine is operable. Mill-wright costs and downtime are minimized.

SMOOTHER MACHINE OPERATION

Micorox Grouts high flow rate and penetration offers minimal shrinkage, complete fill under machine bases. . . fills cracks and voids to rebuild and strengthen foundations and absorb impact and vibrations

QUICK REGROUTING

Micorox grouting techniques eliminate removal and resetting of your machine in many cases. Just raise and re-level – then re-grout. Reduce downtime from weeks to as little as one day.

EASIER SETTING OF ANCHORBOLTS

Eliminate expensive equipment for punching wide holes in concrete. All you have to do is drill a hole the size of the bolt-head and grout.

HIGH CHEMICAL RESISTANCE

Once set up, Micorox Epoxy Grouts are unaffected by water, humidity, oil, grease and most chemicals.

CONVENIENT ALL IN ONE PACKAGE

All components are packed in the mixing container. Materials are pre-proportioned for easy mixing and placing. Micorox Grouts are just a few of the industrial and commercial polymer systems available from Micor Co., Inc. Other unique products include:

• Specialty flooring systems: industrial and commercial.

• Complete line of industrial polymer tank liners and backing systems.

MICOROX® EPOXY GROUT APPLICATIONS

Compressors

Lathes

Pumps

Can Makers

Engines

Column Bases

Electric Motors

Self-Leveling Bases

Generators

Presses

Crushers

Paper Machines

Sole Plates

Blasters

Anchor Bolts

Foundations

Fulcrum Pedestals

Mill Machines

Rails

X-ray Machines

Grinding Machines

Sensitive Equipment

Punch Press

Truck Scales

Shears

Floor Plates

Tank Bases

Punches

Hoist and Jib-Crane Bases

Step 1- Level Machine with 1/4″3/4″ Clearance

Step 2- Dam Perimeter Leaving Adequate Venting

Step 3- Mix Micorox Grout (2 – 3 minutes)

Step 4- Pour Under Machine and Let Harden